Convert your press to an LED-UV!

If you own a 52DI we can convert your system to LED-UV right in your pressroom. LED-UV is also available as a complete system with a newly remanufactured 52DI digital offset press.

Instant Drying, Rich Vibrant Colors

The LED-UV add-on system instantly dries sheets at delivery so you can immediately run your second side or head straight to finishing. With drying time removed, your overall job turnaround time is faster than ever. Your customers will be equally impressed with the DI LED-UV's ability to produce rich, vibrant colors on virtually all stocks!

Greater Substrate Versatility

With LED-UV, instead of printing on just standard paper and board, you can easily add plastic and vinyl into the mix. Expand your business capability with a wider range of print offerings such as packaging, gift cards, hang tags, labels, tickets and more!

Waterless Printing Yields Higher Precision

The Presstek DI's waterless printing design results in less waste, a wider color gamut, less dot gain, and enables you to get up to color fast so you don't have to waste time with unnecessary adjustments. You're saving time and resources without any compromises.

On Press Chemistry-Free 300 LPI Imaging

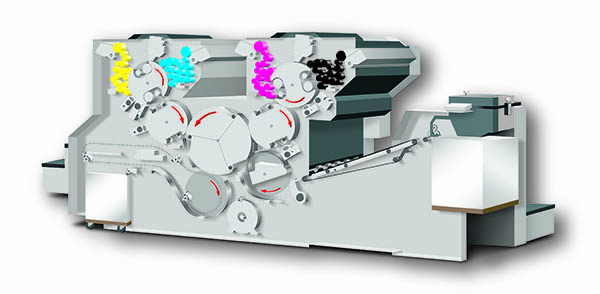

Presstek's patented thermal laser imaging technology means you don't have to worry about costly click charges or hazardous processing chemistry. The press' unique V-shaped design encompasses a central impression cylinder and single gripper system resulting in no-hassle precise registration every time. These digital efficiencies and smart mechanics combined with high quality 300 LPI imaging is what DI is all about!

Set and Forget Plate Media

With a Presstek 52DI LED-UV, 4 spools of media are inserted into the press, then automatically tensioned, imaged, cleaned and advanced so you don't have to swap out media for 44 jobs-- just set it and forget it!

Low Energy Compared to Standard UV

Right out of the gate you're set up to save with Presstek DI LED-UV. Our LED-UV curing systems require significantly less power than standard UV. In addition, our UV curing diodes / lamps are installed inline near the sheet delivery and a small external cabinet takes only a very small amount of floor space - in fact on the 34DI press model the UV cabinet is roughly the same size as a computer server box!

|

Specifications |

| Maximum Print Speed |

10,000 sheets per hour |

| Sheet Orientation |

Landscape |

| Sheet Thickness |

0.0024” – 0.02” (0.06 – 0.5mm) |

| Maximum Sheet Size |

20.47” x 14.76” (520 x 375 mm) |

| Image Resolution / Imaging Time |

2540 dots/in (100 dots/mm) / 4.5 minutes |

| Automated Changeover |

10 minutes |

| Ink Zones, Rollers / Form Rollers |

16 ink zones / 15 ink rollers per unit / 4 form rollers |

| Feeder |

Rotary Stream Feed with suction feeder board |

| Pile Capacity |

Feeder 19.69” (500 mm) / Delivery 15.75 (400 mm) |

| Sheet Drying Time |

Instant with LED-UV |

Download Brochures

WORLD HEADQUARTERS

Mark Andy Inc.

18081 Chesterfield Airport Rd

Chesterfield, MO 63005

USA: 800-225-4835

Canada: 800-387-3143

Main: 636-532-4433

Service Dispatch & Repair Parts:

877-412-3629 Option 7

ONLINE ORDERING:

shop.markandy.com

MAIN DISTRIBUTION

Mark Andy Print Products

4301 Rider Trail North Suite 500

Earth City, MO 63045

800-225-4835

UNITED KINGDOM

Mark Andy UK Ltd.

Queens Avenue

Hurdsfield Industrial Estate

Macclesfield,

Cheshire SK10 2BN

United Kingdom

+44 (0) 1625 500964

|

|

|

|